Lean In, Wastes Out LLC

to transform challenges

into lasting improvements.

Who We Are

Lean In, Wastes Out LLC is a consulting firm based in Georgia, USA that specializes in Operational Excellence, Industrial Engineering, Continuous Improvement and Lean Manufacturing. We partner with functional leaders across industrial, service, and manufacturing sectors to revolutionize their operational processes.

What We Do

From Lean implementation and process optimization to waste reduction and hands-on training, we empower industrial, service, and manufacturing leaders to streamline operations and drive results.

How We Do It

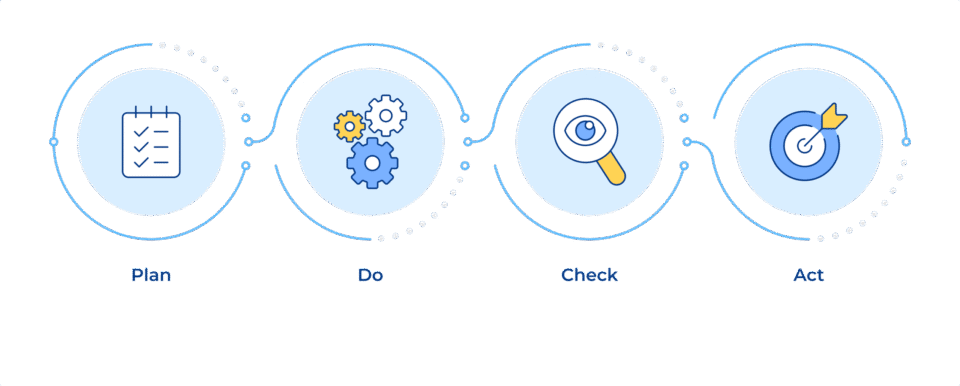

Through a hands-on approach, we work closely with each client to understand their unique challenges and objectives. Our team of experienced consultants provides expertise, guidance, and support throughout the journey toward operational excellence. Lean In, Wastes Out, LLC is your partner in transforming operations, driving efficiency, and achieving a competitive advantage in an ever-evolving industrial landscape.

Summary of Business

Operational Excellence

Industrial Engineering

Continuous Improvement

Our services include Lean implementation, process optimization, waste reduction, and training programs designed to equip teams with the skills necessary to make and sustain improvements. With a proven track record of success, our strategies are crafted to deliver immediate and long-term benefits, ensuring our clients not only meet but exceed their operational goals.

We take a hands-on approach, working closely with every client to understand their unique challenges and goals. Led by our founder, Jena George, our team of seasoned consultants delivers expertise, guidance, and support at every stage of the journey toward operational excellence. At Lean In, Wastes Out LLC, we are your partner in transforming operations, boosting efficiency, and creating a lasting competitive advantage in today’s ever-evolving industrial landscape.

Services We Provide

-

5S

-

Visual Management

-

Value Stream Management

-

Kaizen (Lead or Facilitate)

-

Transactional Process Improvement

-

SMED (Quick Changeovers)

-

Pull Systems

-

Work Cell Design

-

Standard Work

-

Waste Identification

-

Gemba process

-

Training on Lean tools

-

Design & implement Lean war rooms

-

Lean sustainment process for Leadership

-

Autonomous Maintenance

-

Mistake Proofing

-

Time Studies

-

Labor (Operators, Technicians/Mechanics, Leaders, etc.) with recommendations

-

Equipment

-

Processes

-

-

Capacity Analysis

-

Equipment layout changes

-

Project Management

-

Root Cause Analysis

-

Fishbone

-

A3 Training

-

CEDAC

-

Preparation of Standard Operating Procedures

-

Process-focused training & supporting materials